Homepage » Strip Processing Technologies » key technologies » Leveling technology (Levelflex, PMR, MultiRoll, Driven…)

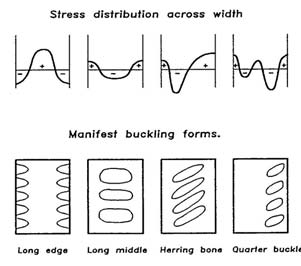

Stretch the shorter fibers to make all of the fibers the same length.

It is the goal of tension leveling!

REDEX Group provides the widest range of leveler in the world:

Upon customers’ performances requests and material type to be processed our experts will provide the best solution for your application.

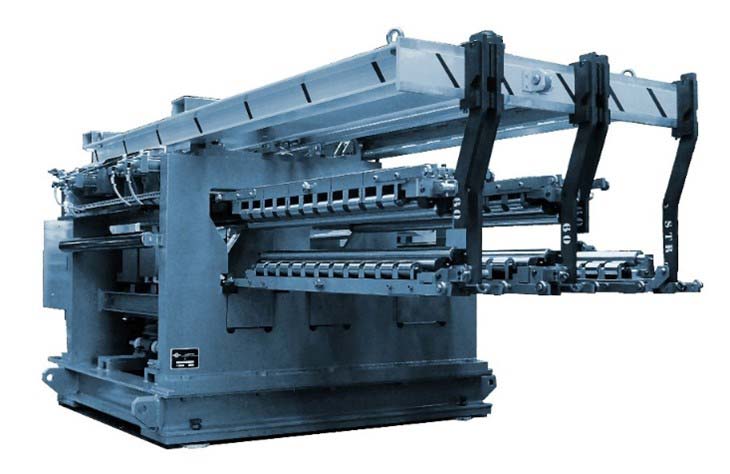

Each unit can be supplied with automatic cassette changing device, fast opening for welding pass.

Specific compact design is available for tinning line tension leveling section.

Our PMR solution installed at the entry of your line improves a lot the double reduction strips quality.

On stand alone lines when numbers of bridle rolls are installed it is dangerous and long to manually introduce the strip in the line.

REDEX Group provides different solutions to thread the strip from decoiler to recoiler: welder, stitcher, threading device are available depending on the material to be processed.

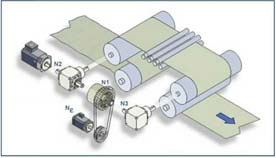

The strip tension is provided through elongation i.e. by speed difference and torque control between bridle roll units on each side of the leveler through individual gear AC motors.

The algorithm ensures the tension distribution among particular drives of the tension leveler while respecting the physical limits of the drives and also preserving the desired conditions of a constant ratio between the input and output tensions for all drives in the leveler. The algorithm also prevents overloading of the drives.

The precise control is made by an electrical gearing of each bridle roll.

SIEMENS S7-1500 PLC TIA Portal, COMPLETE DRIVE TECHNOLOGY S120 and ASYNCHRON 1PH8 MOTORS can provide the best efficiency and the highest speed control accuracy

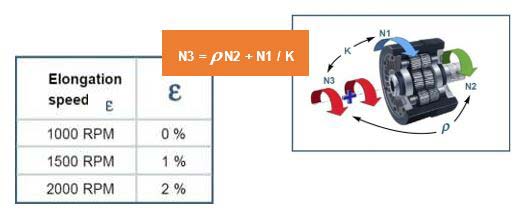

When the speed of the levelling section is highly variable, REDEX elongation box which is designed with an integrated differential driven by AC motors with a specific electronic control is the easiest solution to get the best and constant elongation. The association differential/AC motor provides a high accuracy in speed difference i.e. a high accuracy of strip elongation: ± 0,05 % on absolute value of elongation selected by the operator (usually between 0.20 and 2 %). Elongation remains constant and accurate during line acceleration/deceleration.

Perfectly constant elongation

Independent from electric motor quality and stability.

Defined only by the mechanical fixed ratio of the differential.

High accuracy elongation setting:

Accuracy of elongation motor divided by K

(ex: 0.01 % / 25 = 0.0004 %)

By principle, REDEX elongation control is precise from 10 m/min up to high speed.

After hot rolling, steel producers request pickling lines to process more and more advanced steel grades with the highest efficiency for optimizing downstream processes.

REDEX Group, leader in tension leveling provides tension leveler type scale breaker (called Scalemaster) at the entry side of pickling tank to break the iron oxide on the strip surface mechanically in order to enrich pickling performance. Our Scalemaster carries out dry leveling on the strip with hydraulic quick open function.

Based on an in-depth understanding of all types of metals, from low carbon steel to the most advanced alloys, our experts have designed the Scalemaster with an extremely high stiffness.

This equipment is made of several cassettes on which the strip is bent under tension.

Working roll diameters are calculated according to the material characteristics and the range of thickness.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

REDEX Group is a European Engineering company offering Mechatronics solutions worldwide.

REDEX Group is a European Engineering company offering Mechatronics solutions worldwide.