Homepage » Strip Processing Technologies » key technologies » Skin-Pass Mills

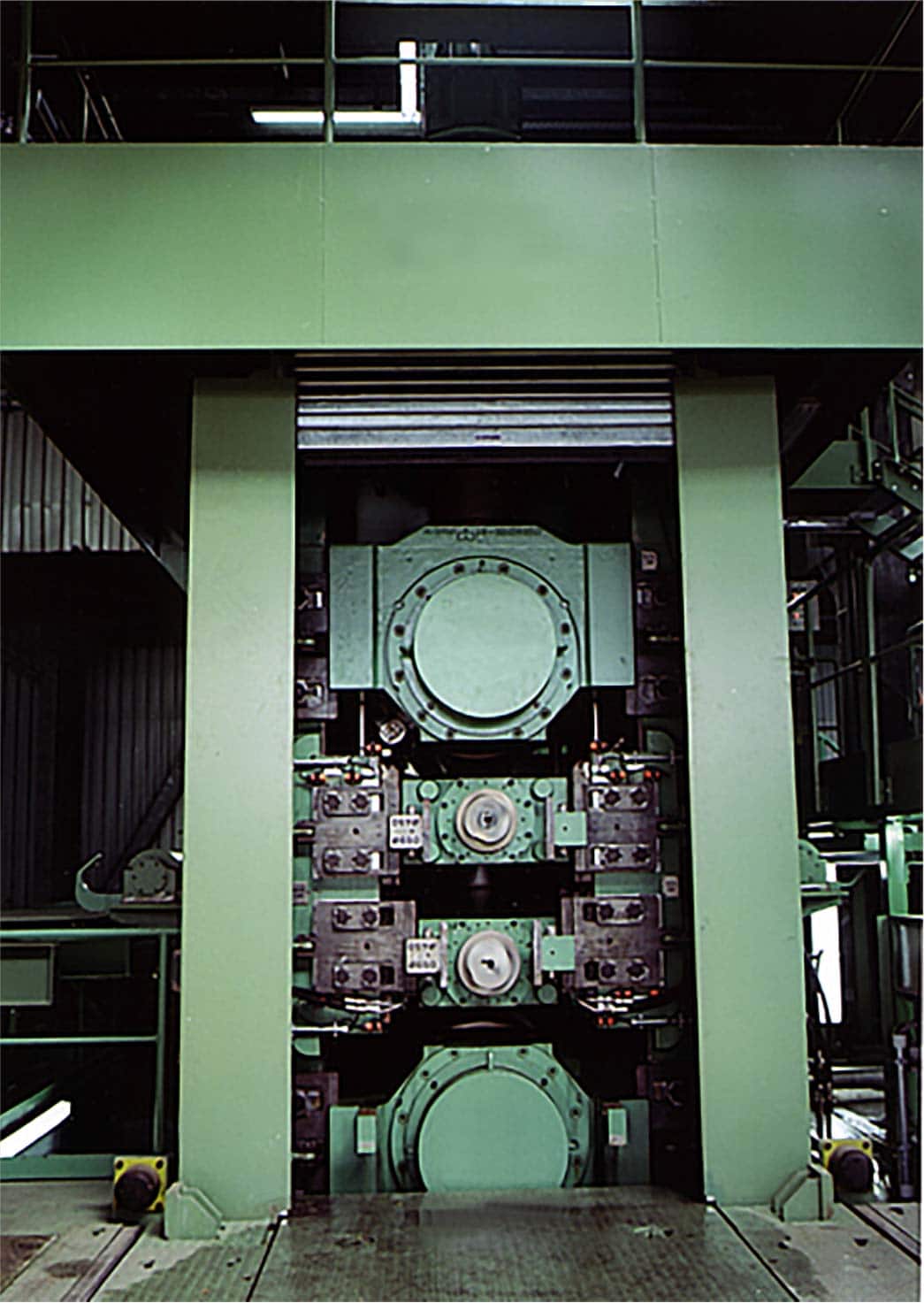

A temper mill is a finishing equipment that processes steel strips in order to give them added strength and uniform flatness to the surface. The metal forming method at a temper mill involves rolling steel strips through a cold reducing process or temper pass. This increases the density of the steel by reducing its overall thickness between usually 1.5% to 2% without allowing the steel to spread out while under pressure.

Our modern temper mills are automated, with each feature in processing being precisely controlled. These features include automatic constant rolling force and elongation controls, as well as automated position and tension controls.

Our group carried out among other developments some innovative and patented technologies such as our specific high precision rolling mill adjustment and control systems and efficient cleaning devices for back up roll and working rolls.

REDEX Group also provides Skin pass mills dedicated to combined galvanizing and coating lines.

This 4 high technology with automatic quick Working rolls change is a good and compact solution for end users looking to low capex investment, low exploitation cost and higher quality of galvanized strips for construction application.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

REDEX Group is a European Engineering company offering Mechatronics solutions worldwide.

REDEX Group is a European Engineering company offering Mechatronics solutions worldwide.