Homepage » Strip Processing Technologies » key technologies » Precision edge trimming section

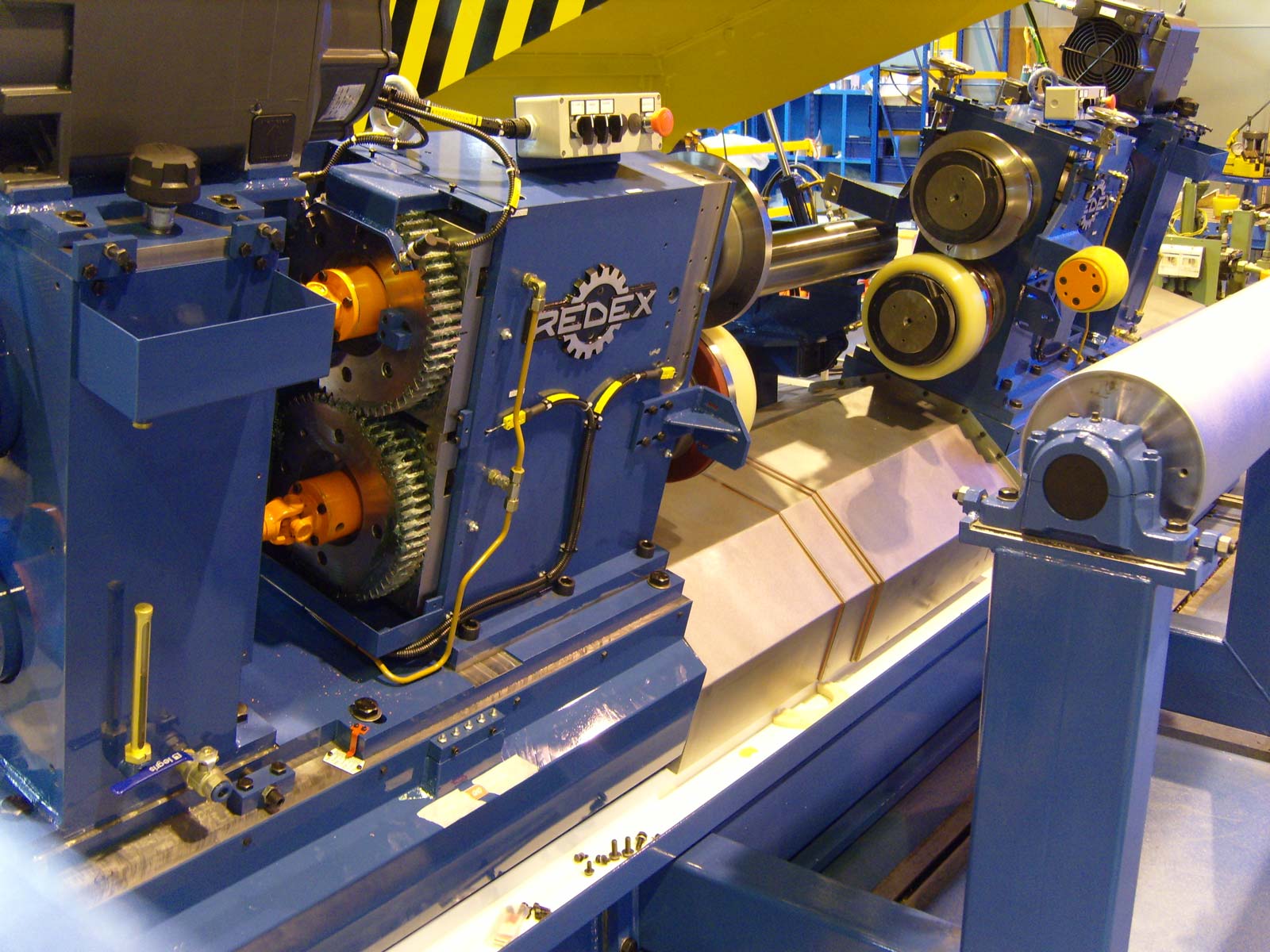

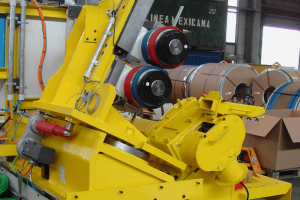

Simple side trimming, double-side trimming shears all work according to the rolling-cut principle. Driven trimming for thin material (0,1 mm) and non driven for thick materials (9 mm) are the state of the art which has been developed by REDEX Group during more than 20 years.

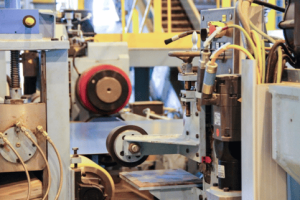

Our modern side trimmer in combination with a scrap cutter increases the line capacity and achieves accurate trim width, minimum burr and knife wear as well as high machine reliability. The top and bottom knives are arranged so that the trim scrap is deflected downward into hardened chutes which guide it into a scrap cutter.

The knives can be found on their faces. A readjustment of the cutting gap after knife change is not required. Scrap ballers are also available with automatic loading of the trim and automatic extraction of the ball into a bin.

To improve the shape of the cutting edges, a horizontal and a vertical knife gap adjustment system. With this system, the cutting gap can be freely adjusted to suit the thickness and quality of the material.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

REDEX Group is a European Engineering company offering Mechatronics solutions worldwide.

REDEX Group is a European Engineering company offering Mechatronics solutions worldwide.